Pre-Treatment [Filtration]

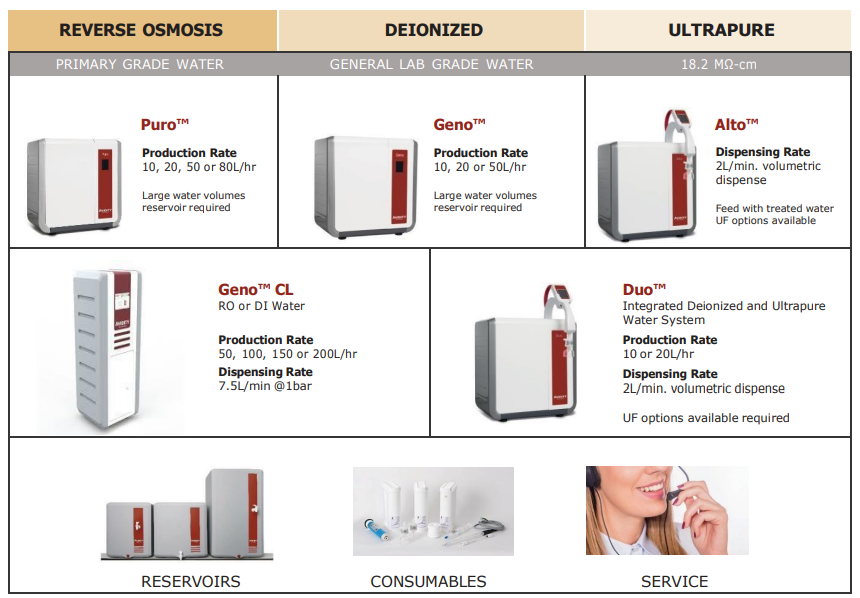

Type 3 Water [Reverse Osmosis (RO) Water Systems]

Applications: Autoclave Feed, Feed To Ultrapure Systems, Sterilizer Feed,Hydroponics, Steam Generators

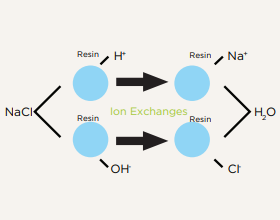

Type 2 Water [Deionization (DI) / Ion Exchange Water Systems]

Applications: Buffer & Media Prep, Glassware Washing / Rinsing, Sample Dilution & Reagent Prep, Photometry, Protein Electrophoresis, Cytology & Histology)

Type 1 Water [Ultraviolet (UV) Photo Oxidation & Ultrafiltration (UF)

Applications: Molecular Biology, Electrochemistry, Critical Cell & Tissue Culture, (GF) AAS, HPLC, IC, ICPMS, GC, MS, DNA Sequencing, Genomics, Proteomics, Immunology, Pharmacology

Consumables & Accessories

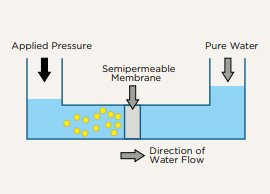

This is the most economical method of removing up to 99% of feed water contaminants. During natural osmosis, water flows from a less concentrated

solution through a semipermeable membrane to a more concentrated

solution until concentration and pressure on both sides of the membrane

are equal. In water purification, external pressure is applied to the more

concentrated side of the membrane to reverse the natural osmotic flow. This

forces the feed water through the semipermeable membrane. The impurities

are deposited on the membrane surface and flushed to drain.

Photochemical oxidation and ultraviolet light eliminate trace organics and inactivate microorganisms in feed water. The 254nm light reacts with bacterial DNA resulting in denaturation. The 185nm light breaks up long chain organics which can then be removed from the water by ion exchange.

Ultrafiltration is used to remove pyrogens (bacterial endotoxins) and nucleases. This process is critical when producing water for use in tissue or cell culture and media preparation. Ultrafilters use size exclusion to remove particles and macromolecules. Ultrafilters are usually employed at the end of the system to ensure near total removal of macromolecular impurities like

pyrogens, nucleases and particulates.

[forminator_form id=”13102″]